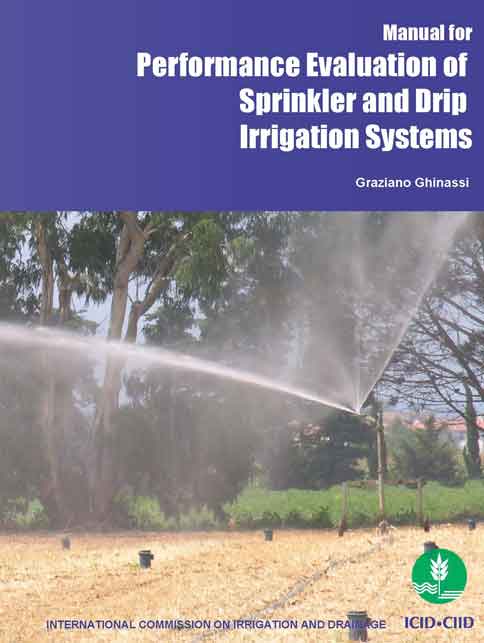

In pressurized irrigation systems water is pressurised and precisely applied to the plants under pressure through a system of pipes. Pressurized irrigation systems, as opposed to the surface irrigation systems, are more effective in application of irrigation water to the crops. They provide improved farm distribution, improved control over timing, reduced wastage of land in laying field distribution network, reduced demand for labour and better use of limited water resources.

There are many variations of pressurized irrigation systems but the two major ones are: drip irrigation systems and sprinkler systems. Among them, there are many variations depending on the type of field, the crop and the kind of water delivery fittings needed, but the components of the basic system remain the same. They consist of the control station where the pressure is applied; the mains and sub mains, which are pipes of differing dimensions; the manifolds or feeder pipelines; and the laterals or irrigating pipelines equipped with emitters (in drip irrigation systems) or other fixtures delivering water to plants or spray booms for forage and grains and centre-pivot systems (in sprinkler systems).Fertilizer injectors can be incorporated into pressurized irrigation systems to perform fertigation.

Pressurized irrigation systems have the potential to avoid the water loss related to surface irrigation increasing the open irrigation application efficiency from 45%- 60% to pressurized irrigation with efficiency in the range of 75% 95%. While open canals systems have high labour requirement for maintenance pressurised systems have skilled labourrequirements. Pressurized irrigation systems need from one-tenth to one-quarter of the man hours canal systems require.Driven by needs to reduce labour input into agriculture and the love of high technology, pressurized irrigation systems are costly and out of reach of small-holder farmers in developing countries.

Water quality and energy are crucial to the sustainability of pressurized irrigation systems. Water with high dissolved minerals leads to frequent blocking of emitters. Routine maintenance is needed to unblock delivery fittings and to maintain pumps and fertigation units.

Pressurized irrigation systems range from sophisticated computer controlled setups with high start-up costs to moderate-cost systems that include bubblers,mini-sprinklers for orchards and micro-sprinklers. Their use has largely been confined to large farmers or in commercial farming.

Pressurized irrigation systems for small-holders have recently been popularized. Examples of lower-cost systems are drip irrigation with drip emitters, drip tape and porous-wall pipes, as well as the hand-moved hose basin system for trees, pipe distribution irrigation systems and hose-move sprinklers.

Related items you may like

Irrigation

Sources of Irrigation

Irrigation History +

Sources of Irrigation +

IMPROVING SOIL MOISTURE +

Ponds +

Tanks +

Diversion Weirs +

Dams and Reservoirs +

Groundwater +

Conjunctive Water Use +

Wastewater +

Poor Quality Water +

Application of Irrigation water

Canal Irrigation +

Flood Irrigation +

Deficit Irrigation +

Supplemental Irrigation +

Sprinkler Irrigation +

Drip Irrigation +

Lift Irrigation +

Centre Pivot Irrigation +

Tidal Irrigation +

Micro-Irrigation Technologies for Small Holders +

Automatic Irrigation Systems +

Pressurized Irrigation +

Irrigation in Viticulture +

Purpose of Irrigation

Instruments and implements of Irrigation

Pumps +

Centrifugal Pumps +

Submersible Pumps +

Turbine and Jet Pumps +

Conveying Pipes +

Sprinklers +

Drippers +

Canal Automation Systems +

Irrigation Management

Economics of Irrigation System +

I&D System Types +

I&D Investment Functions +

I&D Management Issues +

Participatory I&D Management +

Equity in Irrigation +

Irrigation Services +

Irrigation and environment

Pollution and Irrigation +

Irrigation and Climate Resilience +

Environmental Aspects of Irrigation +

Environmental Impacts of Irrigation +

Green Lawn Irrigation +

Safe Use of Waste Water in Irrigation +

Organic Agriculture +

Soil Health +

Soil Health Management +

Quality of Irrigation Water +

Capacity Development

Drainage

Drainage Types and Systems

Agricultural Drainage +

Field Drainage systems +

Canal Irrigation and Drainage +

Surface Drainage Systems +

Subsurface Drainage +

Mole Drainage +

Bio-Drainage +

Regional Bio-Drainage +

Drainage Issues

- Irrigation pipe aqueduct, Pipe aqueduct, Pipe flume

- Syphon, Inverted siphon, Irrigation syphon, Canal syphon, Syphon superpassage

- Lift irrigation area, or Lift area

- Continuous-flow irrigation

- Night-storage irrigation system

- Intermittent-flow irrigation system

- Irrigation return flow

- Farm irrigation structures

- Collective irrigation system

- Individual irrigation system

- Perennial irrigation

- Seasonal irrigation

- Supplemental irrigation

- Systematic irrigation

- Flow irrigation, or Gravity irrigation

- Pumping irrigation

- Inundation irrigation

- Irrigation from a storage reservoir

- Irrigation from groundwater

- Irrigation by flood water spreading

- Sailab irrigation (a term used in India and Pakistan)

- Micro basin irrigation

- Irrigation by spreading

- Irrigation

- Irrigation interval

- Irrigation dose

- Ideal irrigation interval

- Irrigation season

- Fall irrigation (USA)

- Winter irrigation (USA)

- Early irrigation (USA)

- Sub-irrigation

- Overirrigation

- Irrigation canals

- Surface irrigation

- Flood irrigation

- Basin method of irrigation, or Irrigation by beds

- Flush irrigation

- Spate irrigation

- Border irrigation, or Border method

- Flooding from ditches, or (contour ditch irrigation)

- Corrugation irrigation

- Furrow irrigation

- Surge irrigation

- Duration of irrigation

- Secondary flow, Two discharge, or Cutback irrigation

- Primary flow irrigation (single discharge)

- Wave irrigation

- Irrigation through buried drains, Irrigation-drainage, or Vallenhove process

- Irrigation by nappe control, or Ramspol process

- Selection of irrigation parameters

- Sprinkler irrigation

- Irrigation terminal

- Irrigation device

- Perforated pipe sprinkler irrigation

- Irrigation sprinkler machine

- Centre pivot irrigation

- Lateral-move irrigation machine sprinkler method

- Solid set irrigation

- Piloting of irrigation

- Irrigation cycle

- Micro-irrigation, Localized irrigation, Drip irrigation, Trickle irrigation

- Mobile micro-irrigation

- Pulse irrigation

- Surface drip irrigation

- Buried drip irrigation

- Drip irrigation functioning by propulsions

- Micro-irrigation network

- Micro-irrigation nozzle-line

- Irrigation dose

- Semi-automatic control (of irrigation)

- Micro-irrigation system with hydraulic sequential operation

- Automatic control (of irrigation)

- Porous wall microirrigation tubing

- Proportional irrigation pump

- Irrigation water

- Irrigation water requirement, Irrigation need

- Net irrigation requirement, Farm delivery requirement, or Delta at farm

- Crop irrigation requirement

- Diversion requirement, Gross irrigation requirement, or Delta at head of main canal

- Optimum irrigation requirements

- Irrigation efficiency, Farm irrigation efficiency, Farm delivery efficiency, Water conveyance and delivery efficiency, or Overall efficiency

- Irrigation water-requirement

- Subirrigation

- Surge irrigation

- Irrigation water use efficiency

- Unit irrigation efficiency

- Economic efficiency of irrigation

- Irrigation efficiency

- Agronomic efficiency of irrigation or Agronomic productivity of irrigation

- Degree of durability of irrigation

- Programmed irrigation

- Fully automatic irrigation system

- Irrigation development project or system

- Irrigation

- Surface irrigation

- Basin Irrigation

- Overhead irrigation

- Sub‑irrigation

- Microirrigation

- Trickle irrigation

- Drip irrigation

- Total irrigation

- Supplemental irrigation

- Preplant irrigation

- Organic irrigation

- Conjunctive irrigation planning

- Irrigation project

- Irrigation potential

- Assessment of irrigation charges

- Irrigation cess

- Water rate, Water charge, Irrigation rate, or Irrigation assessment

- Primary benefits, Primary effects, Direct irrigation benefits, or Direct irrigation effects

- Secondary benefits, Secondary effects, Indirect irrigation benefits, or Indirect irrigation effects

- Economic value of unit of irrigation water

- Revenue value of a unit of irrigation water